About Biogas Plants

ORCCI Eco Products designs and supplies complete biogas plant equipment engineered for safe, efficient and long-term conversion of organic waste into renewable energy. Our systems are modular, scalable and optimized for Indian waste conditions.

Industrial Canteen: Tailored anaerobic digestion systems that convert kitchen food waste into clean cooking gas for large-scale facilities.

Institutions (NAAC): Strategic waste-to-energy implementations designed to help educational institutions meet sustainability benchmarks and NAAC accreditation.

Domestic Biogas Plant: Compact and user-friendly biogas units designed for efficient onsite waste management in residential settings.

Biogas for Electricity: Integrated power solutions that utilize refined biogas to fuel specialized generators for renewable energy production.

Efficiency & Features: High-performance systems focused on safety, longevity, and maximum gas yield through sustainable engineering.

Our Products & Services

Biogas for Industrial Canteen

Tailored biogas systems for factories, IT parks, hospitals, and large industrial kitchens. Designed to process high volumes of food waste and generate consistent gas output for daily cooking needs.

- Reduces LPG consumption by up to 70%

- Handles bulk organic waste efficiently

- Continuous, reliable gas generation

Biogas for Institutions (NAAC)

Eco-friendly waste-to-energy systems ideal for schools, colleges, and residential hostels. Fully compliant with NAAC and Swachh Bharat sustainability standards.

- Supports NAAC accreditation requirements

- Manages daily food waste from hostels/mess

- Promotes green campus initiatives

Domestic Biogas Plant

Compact and user-friendly biogas units for homes. Converts kitchen waste into clean cooking gas and produces organic fertilizer for plants.

- Daily kitchen waste → free cooking gas

- Safe, odor-free, low maintenance

- Ideal for households, small farms, and apartments

Biogas for Electricity

Advanced power generation systems using biogas engines and generators. Suitable for farms, industries, and commercial buildings requiring off-grid or hybrid energy solutions.

- Continuous electricity generation

- Reduces diesel generator costs

- Perfect for rural and industrial energy needs

Efficiency of Biogas Plant

The efficiency of a biogas plant depends on the quality of feed material, temperature, retention time and overall design. A well-designed system can convert 60–70% of the organic content into usable biogas.

Modern biogas technology ensures high gas yields through optimized digestion processes, continuous mixing, and proper temperature regulation. Regular maintenance and slurry management further improve overall performance.

- Optimized gas production from organic waste

- Higher methane content (55–65%) for better energy output

- Low operational cost with long-term savings

- Stable and continuous gas generation

- Eco-friendly and highly scalable for different applications

Sustainability

Biogas plays a vital role in building a sustainable future by transforming organic waste into clean, renewable energy. It supports circular economy practices by creating value from waste streams and reducing dependence on fossil fuels.

Through methane capture and controlled digestion, biogas systems significantly lower greenhouse gas emissions. The nutrient-rich slurry produced during digestion is a natural fertilizer that improves soil health and reduces chemical fertilizer use.

- Promotes zero-waste and circular economy models

- Reduces carbon emissions and supports climate goals

- Converts waste into energy with minimal environmental impact

- Produces organic fertilizer that enhances soil quality

- Encourages sustainable agriculture and rural development

Biogas Case Studies

Our biogas installations across industries, institutions, and communities demonstrate the practical impact of turning organic waste into clean, sustainable energy. These case studies highlight real-world performance, energy savings, operational efficiency, and long-term benefits experienced by our clients.

Biogas Brochure Download

Download our detailed biogas brochure to learn more about our technology, products, services, plant designs, and real-world applications. Get complete technical specifications and benefits in one place.

Download Brochure (PDF)Biogas Accessories

Biogas accessories play a crucial role in enhancing the efficiency, safety, and usability of any biogas plant. From purification to pressure regulation, each accessory ensures smooth and reliable operation. High-quality components help maintain gas purity, prevent leakage, improve combustion, and extend the lifespan of the biogas system.

Whether it’s burners, filters, pressure regulators, pipelines, or gas storage solutions, the right accessories ensure consistent performance and maximum energy output while keeping maintenance needs low. These components are essential for both domestic and industrial biogas setups.

- FRP DIGESTER

- GAS HOLDER (Floating Dome)

- MOISTURE SEPARATOR

- BIOGAS STORAGE BALLOON

- BIOGAS STORAGE BALLOON

- Biogas Flow Meter

- FLAME ARRESTER (SS 304)

- AIR BLOWER

- GAS PIPELINE SYSTEM

- CANTEEN BURNER STOVE

1. FRP DIGESTER

The FRP Digester is the core anaerobic digestion chamber where organic waste is biologically converted into methane-rich biogas and nutrient-rich digestate. Designed for stable operation, it ensures high gas yield and odour-free performance.

Key Features

- High-strength, corrosion-resistant FRP construction

- Fully enclosed, gas-tight design

- Optimized geometry for uniform digestion

- Suitable for food waste and organic waste

- Long service life with minimal maintenance

2. GAS HOLDER (Floating Dome)

The Gas Holder provides safe storage and pressure balancing of biogas, ensuring a steady and controlled gas supply to end-use systems.

Key Features

- Floating dome design for automatic pressure regulation

- FRP / MS construction with gas-tight sealing

- Stable gas flow to burners, boilers or gensets

- Built-in safety provisions

- Designed for continuous operation

3. MOISTURE SEPARATOR

Moisture Separators remove condensed water from biogas pipelines, protecting downstream equipment and ensuring smooth gas flow.

Key Features

- Prevents corrosion and pipeline blockage

- Improves safety and system reliability

- Low pressure drop

- Compact and easy to install

- Low maintenance operation

4. FOOD WASTE CRUSHER

The Food Waste Crusher converts food waste into a uniform, pumpable slurry, improving digestion efficiency and biogas yield.

Key Features

- Efficient size reduction and homogenization

- Reduces clogging in feeding systems

- Enhances microbial digestion

- Robust, heavy-duty construction

- Ideal pre-treatment unit for food waste biogas plants

5. BIOGAS STORAGE BALLOON

Biogas Storage Balloons provide flexible intermediate gas storage, balancing variations between biogas generation and consumption.

Key Features

- Gas-tight and weather-resistant membrane

- Flexible capacity for load balancing

- Improves operational stability

- Easy installation and handling

- Low maintenance design

6. Biogas Flow Meter

Biogas Flow Meters enable real-time measurement of gas production and consumption, supporting performance monitoring and optimization.

Key Features

- Accurate biogas flow measurement

- Supports process optimization

- Helps detect leaks and abnormalities

- Reliable and low maintenance

- Suitable for continuous monitoring

7. FLAME ARRESTER (SS 304)

The Flame Arrester is a critical safety device that prevents flame flashback from burners or flares into the biogas system.

Key Features

- SS 304 construction for durability

- Prevents fire and explosion risks

- Enhances overall plant safety

- Easy installation and maintenance

- Essential for all biogas plants

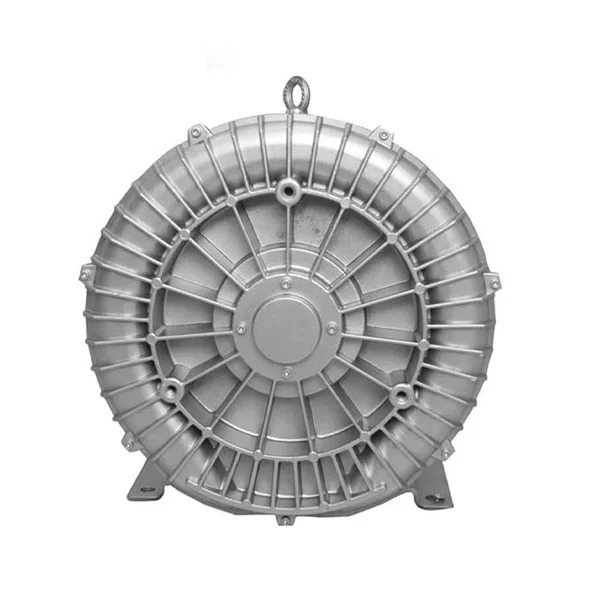

8. AIR BLOWER

Air Blowers supply controlled air for stable and efficient biogas combustion, ensuring smooth burner and flare operation.

Key Features

- Regulates flame intensity

- Improves combustion efficiency

- Stable and reliable performance

- Low power consumption

- Suitable for burners and flaring systems

9. GAS PIPELINE SYSTEM

The Gas Pipeline System ensures safe, leak-proof biogas distribution from the digester to utilization points.

Key Features

- CPVC or flexible gas hose options

- Corrosion-resistant materials

- Secure joints and fittings

- Easy installation and routing

- Designed for long-term safety

10. CANTEEN BURNER STOVE

The Canteen Burner Stove is a heavy-duty biogas burner designed for continuous cooking in institutional and industrial kitchens.

Key Features

- Stable and uniform flame

- Designed specifically for biogas fuel

- Multiple capacity options available

- Robust and durable construction

- Easy and safe operation

11. CONTROL PANEL / PANEL BOARDS

Panel Boards provide centralized control and monitoring of biogas plant equipment and safety systems.

Key Features

- Centralized operation and monitoring

- Integration of sensors and interlocks

- Improves safety and process control

- User-friendly interface

- Reliable and low maintenance

12. BIOGAS FLARING SYSTEM

Biogas Flaring Systems offer a safe and controlled method for disposing of excess or unusable biogas.

Key Features

- Controlled combustion of surplus gas

- Prevents gas accumulation and overpressure

- Reduces methane emissions

- Reliable and low maintenance

- Supports environmental compliance

13. H₂S SCRUBBER

H₂S Scrubbers remove hydrogen sulfide from biogas, protecting equipment and improving gas quality.

Key Features

- Reduces corrosion in pipelines and burners

- Improves safety and gas usability

- Enhances life of downstream equipment

- Low maintenance operation

- Suitable for various biogas applications

14. BIOGAS UTILIZATION SYSTEMS

ORCCI Eco Products supplies integrated biogas utilization solutions for thermal and electrical applications..

Applications

- Cooking and heating systems

- Hot water and boiler firing

- Biogas gensets for power generation

- Industrial and institutional use

Benefits

- Efficient energy recovery

- Reduced fossil fuel dependence

- Stable and reliable performance

- Supports circular economy and GHG reduction

Bio Additives

We make your Biogas plant failure-safe

Are you struggling with inconsistent biogas output or unstable digester performance? Biomethanation additives help restore balance, improve microbial activity, and enhance overall plant efficiency. These additives ensure a smooth, reliable, and continuous digestion process — even under challenging operating conditions.

Are You Facing These Challenges?

- Lesser Biogas Production

- Unstable Digester Process

- Challenges with Food Waste Processing

- pH Fluctuation Issues

- Frequent Equipment Breakdowns

- Non-operational or Failing Biogas Plants

If these issues sound familiar, it may be time to address key system inefficiencies. Our specialized biomethanation solutions are designed to optimize digester performance, boost methane yield, and ensure long-term stability of your biogas plant.

1. Biogas Booster Additives

Enhancing Biogas Production:

- Nutrient Optimization – Provides essential nutrients to maximize biogas yield.

- Process Stability – Helps maintain a stable digestion process.

- Wide Compatibility – Works with all feedstock types including complex organic wastes.

2. Biogas Detox

Improving Gas Quality & Process Stability:

- Efficient Gas Purification – Removes NH₃ & H₂S inside the digester.

- Enhanced Methane Production – Improves gas quality and methane yield.

- Corrosion Prevention – Reduces equipment damage and extends life.

- Microbial Optimization – Retains & stabilizes microbial activity.

- Supports Biofilm Formation – Boosts microbial efficiency.

3. Biogas Stabilizer

Ensuring Process Stability & Optimal Biogas Yield:

- Optimized pH Control – Maintains ideal pH for digestion.

- Stable & Reliable Production – Ensures consistent gas output.

- Enhanced Biogas Yields – Supports microbial efficiency.

- Reduced Maintenance – Lowers need for frequent adjustments.

- Increased Reliability – Improves plant performance and stability.